Weaving a Smarter Future: How ASRS & Conveyors Revolutionize the Textile Industry

The textile industry, with its intricate dance of raw materials, work-in-progress, and diverse finished goods, faces a unique set of logistical challenges. From managing vast rolls of fabric to hundreds of thousands of garment SKUs, efficiency, damage prevention, and rapid response to fashion trends are paramount. In India, a global leader in textile manufacturing, optimizing these processes is key to maintaining a competitive edge.

For textile manufacturers, apparel brands, and fashion retailers across Maharashtra and nationwide, the integrated power of Automated Storage and Retrieval Systems (ASRS) stacker cranes and conveyor systems is no longer a luxury – it’s the thread that ties together a smarter, more profitable supply chain.

The Fabric of Challenge: Textile Logistics Hurdles

The sheer variety and physical characteristics of textile products create distinct warehousing complexities:

Bulky & Varied Raw Materials: Managing enormous rolls of fabric, often weighing hundreds of kilograms, requires specialized handling and high-density storage to save space.

SKU Proliferation: The fashion industry’s rapid cycles mean a constant influx of new styles, colors, and sizes, leading to an explosion of apparel SKUs.

Delicate Handling: Fabric and finished garments can be easily creased, soiled, or damaged if not handled with care, leading to costly waste.

Space Constraints: Warehouses often become quickly overwhelmed, especially with seasonal stock build-ups. Maximizing textile storage capacity is crucial.

Seasonal Peaks & Rapid Trends: The industry is highly susceptible to seasonal demand fluctuations and rapid shifts in fashion trends, demanding extreme flexibility and speed in order fulfillment.

Manual Labor Intensity: Traditional methods involve significant manual labor for picking, sorting, and moving, leading to inefficiencies and potential errors.

These challenges highlight the need for intelligent automation that can adapt to the fast-paced and sensitive nature of textiles.

ASRS Stacker Cranes: The Vertical Loom of Textile Storage

ASRS stacker cranes are perfectly designed to bring order and efficiency to the chaotic world of textile warehousing:

High-Density Fabric Roll Storage: ASRS can store massive fabric rolls vertically, utilizing overhead space up to 40 meters. This dramatically reduces the floor footprint needed for raw materials, freeing up valuable space for manufacturing or finished goods.

Garment & Apparel Management: For finished garments (boxed, on hangers, or in totes), ASRS provides high-density, secure storage, often integrated with hang-garment solutions or carton storage systems.

Precision Inventory Control: Every roll, box, or garment tote is precisely tracked by the Warehouse Management System (WMS). This ensures accurate, real-time textile inventory management, preventing mispicks, reducing stock discrepancies, and improving forecasting for apparel production.

Damage Prevention: Automated handling minimizes direct human contact and rough movements, protecting delicate fabrics and garments from creases, stains, or tears.

Enhanced Security: Valuables, such as high-end fabrics or designer apparel, are stored securely in a controlled, lights-out environment, minimizing theft and loss.

Conveyor Systems: The Seamless Thread of Textile Flow

While ASRS optimizes static storage, conveyor systems provide the dynamic, uninterrupted flow of materials that is essential for textile manufacturing and distribution:

Raw Material Delivery: Conveyors can transport fabric rolls directly from receiving or ASRS to cutting tables, sewing lines, or other processing areas, ensuring a continuous supply.

Work-in-Progress (WIP) Movement: Between different stages of garment production (e.g., cutting to sewing, sewing to finishing), conveyors move batches or individual items, reducing bottlenecks and manual handling.

Automated Picking & Sorting: For apparel order fulfillment, conveyors bring picked items from storage to packing stations and then carry finished orders to sortation systems for efficient dispatch.

Returns Processing: Conveyors streamline the reverse logistics process for returned garments, directing them to inspection, re-packaging, or re-stocking areas.

Ergonomics & Safety: Reduce the physical strain on warehouse associates by automating the movement of heavy rolls or large volumes of items, improving overall warehouse safety.

The Integrated Solution: Weaving Operational Excellence

The synergy between ASRS stacker cranes and conveyor systems creates a highly responsive and efficient textile logistics framework:

Automated Inbound: Fabric rolls are automatically transported from inbound docks to the ASRS for storage.

JIT Production Feed: As production requires, specific fabric rolls are retrieved by the ASRS and placed onto conveyors, delivering them precisely to the cutting or dyeing stages.

WIP Management: Partially finished garments move along conveyors between production cells.

Finished Goods Flow: Completed garments are conveyed to the ASRS for high-density storage or directly to automated picking zones.

Rapid Order Fulfillment: For online fashion retailers or apparel distributors, ASRS feeds goods-to-person picking stations, and conveyors then transport packed orders to shipping.

This integrated approach leads to:

Significant Space Savings: Maximize existing warehouse space for textile inventory.

Faster Throughput: Accelerate production cycles and apparel order fulfillment, crucial for fast fashion and seasonal demands.

Reduced Product Damage & Waste: Gentle, automated handling protects valuable fabrics and garments.

Lower Labor Costs: Optimize workforce allocation, reducing reliance on manual handling.

Improved Inventory Accuracy: Real-time visibility into every roll and garment SKU.

Enhanced Responsiveness: Quickly adapt to changing fashion trends and customer orders.

Competitive Edge in India: Modernize textile supply chains to meet global demands.

Future-Proofing Your Textile Operations

For textile manufacturers and apparel brands in Coimbatore, Mumbai, or anywhere in India and beyond, embracing advanced warehouse automation technology like ASRS stacker cranes and integrated conveyor systems is no longer a trend; it’s a strategic investment in sustainable growth and operational excellence. It’s about unrolling new possibilities for efficiency, precision, and profitability in the dynamic world of textiles.

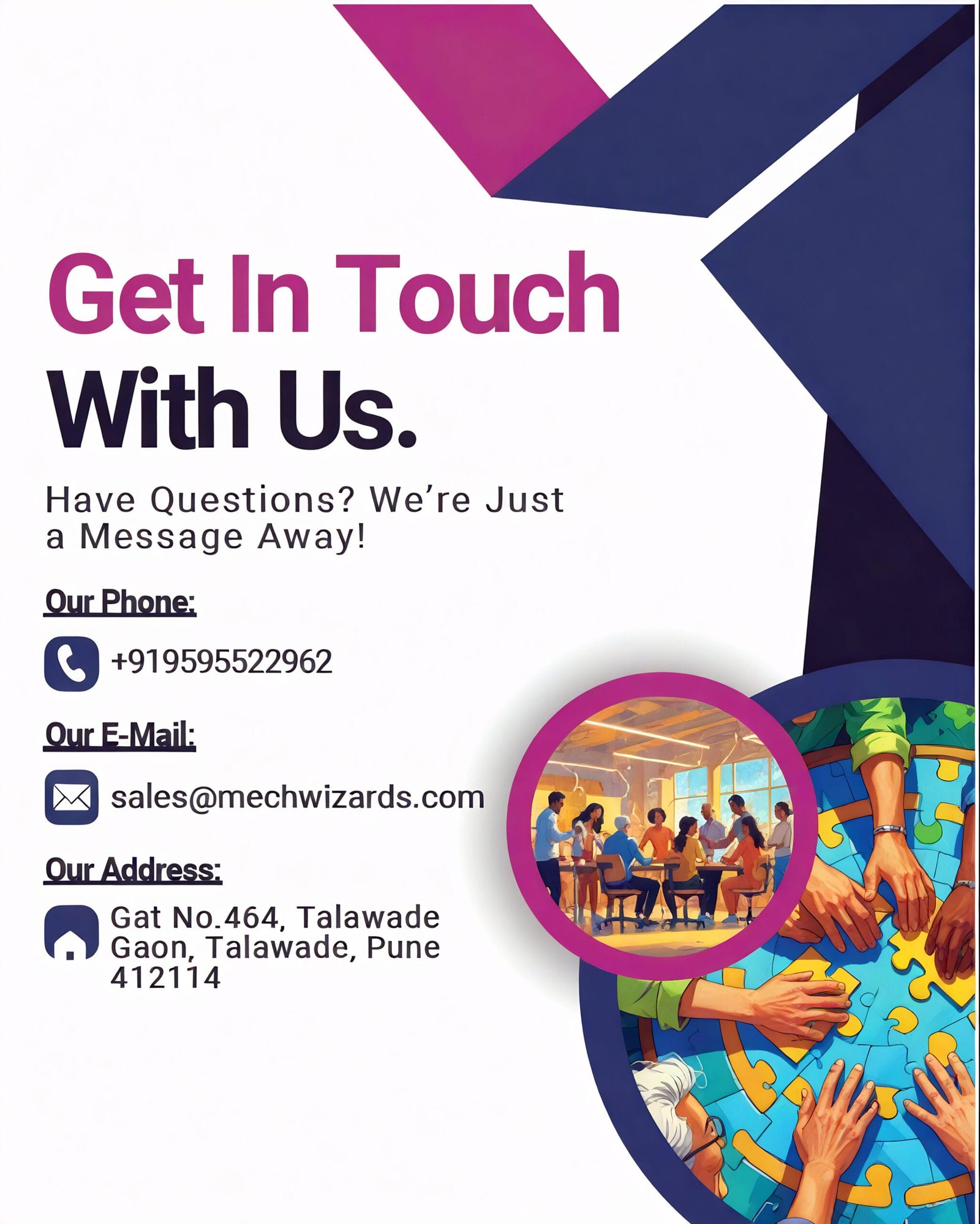

Is your textile or apparel warehouse struggling to keep pace with demand, manage diverse inventory, or prevent product damage? Discover how a tailored ASRS and conveyor solution can weave a smarter, more efficient future for your operations. Contact us today for an expert consultation!