Deep Freeze Efficiency: ASRS Stacker Cranes Leading the Way in Cold Chain Logistics

The cold chain industry is a vital, yet incredibly demanding, component of the global supply network. From pharmaceuticals and frozen foods to delicate chemicals, maintaining precise temperature control is non-negotiable. However, the very nature of low-temperature environments—ranging from refrigerated (0°C to 10°C) to deep freeze (-25°C to -30°C and beyond)—presents unique operational challenges. This is where Automated Storage and Retrieval System (ASRS) stacker cranes emerge as the ultimate solution, enabling unparalleled efficiency, safety, and cost savings in the most challenging of warehouses.

The Icy Reality: Challenges of Refrigerated Warehousing

Operating a cold storage facility is far more complex than a standard dry warehouse. The persistent challenges include:

Sky-High Energy Costs: Maintaining constant low temperatures consumes enormous amounts of energy, making electricity bills a major operating expense. Every time a door opens, or warm air infiltrates, the cooling system works harder.

Harsh Conditions for Human Workers: Extreme cold environments are physically demanding and pose significant health and safety risks to personnel, leading to fatigue, reduced productivity, and higher turnover.

Maintaining Product Integrity: Fluctuating temperatures or prolonged exposure can compromise the quality and safety of temperature-sensitive goods, leading to spoilage, waste, and regulatory issues.

Condensation & Ice Buildup: These issues can create slippery surfaces, damage packaging, and reduce the lifespan of equipment not designed for the cold.

Space Utilization: Building and maintaining temperature-controlled spaces is expensive, making every square foot (and cubic meter) incredibly valuable.

Traditional manual or semi-automated systems often struggle to overcome these hurdles efficiently.

ASRS Stacker Cranes: Built for the Chill

ASRS stacker cranes are not merely “adapted” for cold storage; they are often purpose-built to thrive in these conditions. Their design and operational capabilities directly address the core challenges of refrigerated and freezer warehouses:

Designed for Extreme Temperatures: ASRS components, from specialized lubricants and wiring to robust motors and control systems, are engineered to perform reliably in sub-zero environments, ensuring continuous operation without degradation.

Reduced Energy Consumption: Because ASRS operates within a sealed, high-density environment, door openings are minimized, and the volume of air requiring cooling is significantly reduced. This leads to substantial savings on refrigeration costs.

Eliminating Human Exposure: By automating the storage and retrieval process, ASRS removes the need for human operators to spend prolonged periods in harsh, freezing conditions. This dramatically enhances worker safety and comfort.

High-Density Vertical Storage: ASRS stacker cranes utilize vertical space to its maximum potential, often reaching heights of 40 meters or more. This allows cold storage facilities to store significantly more product in a smaller, more cost-effective footprint, reducing the overall volume that needs to be cooled.

Automated Inventory Control: Precise tracking of every pallet or carton ensures accurate inventory counts, optimal stock rotation (e.g., FIFO for perishables), and real-time visibility into product location, crucial for sensitive goods.

The Frost-Proof Benefits for Cold Chain Logistics

The advantages of integrating ASRS into your cold storage operations are clear and impactful:

Significant Cost Savings: The primary benefit is the dramatic reduction in energy consumption and lower labor costs associated with operating in harsh environments. These savings directly impact your bottom line.

Enhanced Worker Safety: Removing personnel from the extreme cold leads to a safer working environment, reducing the risk of cold stress, frostbite, and slips/falls on icy surfaces.

Improved Product Quality & Integrity: Consistent temperature maintenance and minimal human handling ensure products remain in optimal condition, reducing spoilage, damage, and maintaining regulatory compliance.

Faster Throughput: ASRS can move goods quickly and accurately, allowing for rapid loading and unloading of trucks, faster order fulfillment, and improved overall operational speed.

Reliability & Uptime: Robust systems designed for the cold mean less downtime due to equipment failure, ensuring continuous and reliable operation.

Optimized Space Utilization: Maximize the return on investment for expensive cold room construction or expansion by storing more in less space.

Ready to Chill Your Operational Costs and Boost Efficiency?

In the increasingly competitive and demanding world of cold chain logistics, embracing advanced automation like ASRS stacker cranes is no longer a luxury; it’s a strategic necessity. It’s about creating a more sustainable, safer, and ultimately more profitable cold storage operation.

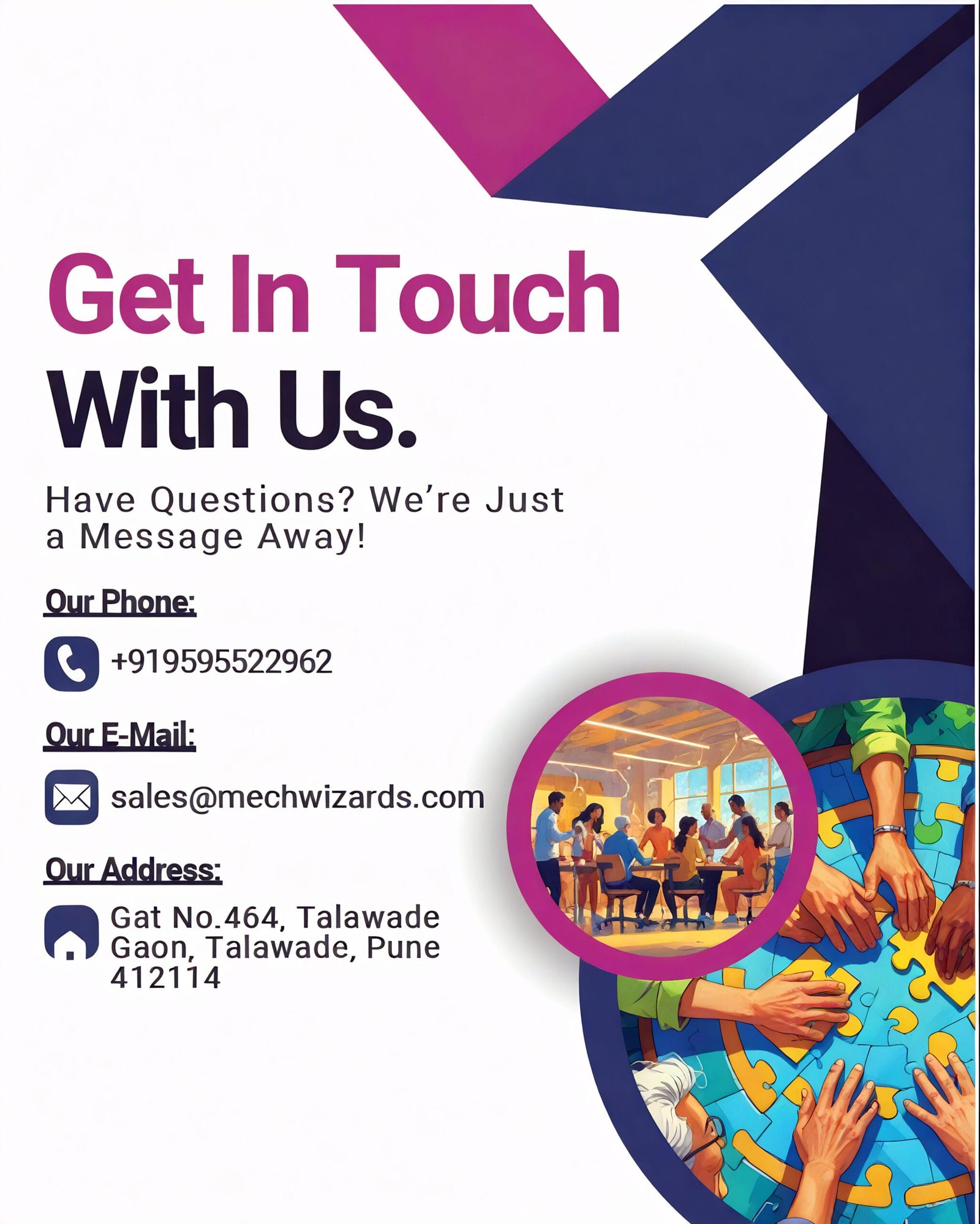

Is your cold storage facility feeling the squeeze of high costs and operational challenges? Let’s discuss how a purpose-built ASRS solution can provide the deep freeze efficiency you need to stay ahead. Contact us today for a consultation!